Capstone Students’ Design to be Used in Production

Mar 2, 2023

EngineeringDuring their 2022 Capstone Project, students from the KUAS Faculty of Engineering tackled an assignment proposed by Matsui Seisakusho Co., Ltd. A mechanical jig, designed by the students as a solution to the proposed problem, will be put into practical use by the company starting in March of this year. Theirs is the first Capstone Project result to be put into service by the partner company.

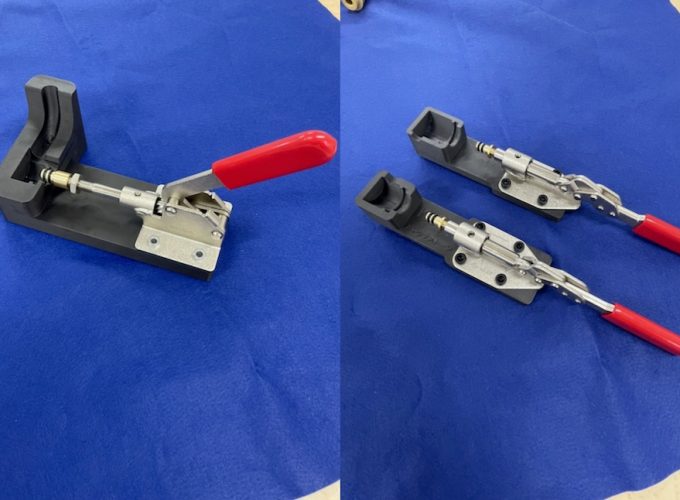

Matsui Seisakusho Co., Ltd., which collaborated with the students on their Capstone, manufactures valves and fittings used in fields such as gas equipment, air conditioners, semiconductors, and medical devices. The engineering students were given the task of making a jig to test metal fittings for leaks. The students used equipment such as 3D printers to create a prototype jig that the company subsequently decided to put into production use.

Daimon Matsui, Managing Director of Matsui Seisakusho, commented, “They proposed a design that we had never thought of in the company, from a student’s unique point of view, and we decided that the actual degree of perfection would stand up to practical use.”

In 2023, approximately 200 third and fourth-year students from the Faculty of Engineering at KUAS will undertake Capstone Projects, choosing between more than 40 different problems proposed by 30 partnering companies.

Comments from the Capstone Project Team Members

Shinya Kato: “It is such an accomplishment that the jig that we designed, prototyped, and manufactured can be used in the actual inspection process. I am very happy that our work is now contributing something to the actual production site.”

Kouki Hattori: “I am very pleased that we were able to put the results into practice. We hope that the jig we made will contribute to the production site.”

Ryusei Maeda: “I really learned a lot from our partners of Matsui Seisakusho. With this experience, I would like to build my career as an engineer working in overseas.”

Ryo Mitani: “Thanks to everyone in Matsui Seisakusho and the team members of this product. I believe that is our teamwork to achieve this output. I am very pleased to see the results of this Capstone Project.”

(Tadayuki Imai, Faculty of Engineering)

(Go Urata, Public Relations Center)